Exposure system for compound semiconductor (mask aligner)

Exposure system that prints patterns on photoresist-coated substrates aligned with a mask, in which an automatic alignment mechanism is available for multi-layer exposure. Substrate loading, alignment, exposure, and unloading are performed automatically.

Features

- Our original parallelization mechanism enables making a proximity gap between a mask and a wafer with high accuracy.

- Our original high speed image processing technique realizes high accuracy alignment.

- The image processing technique can enable propositioning a thin, warped or fragile wafer such as quartz (optional).

- Our original precision contact-pressure control mechanism enables a wafer to contact a mask with high accuracy.

- A vacuum chuck is employed to fix a wafer on its back side, realizing high speed & accuracy and stable automatic transfer of the wafer.

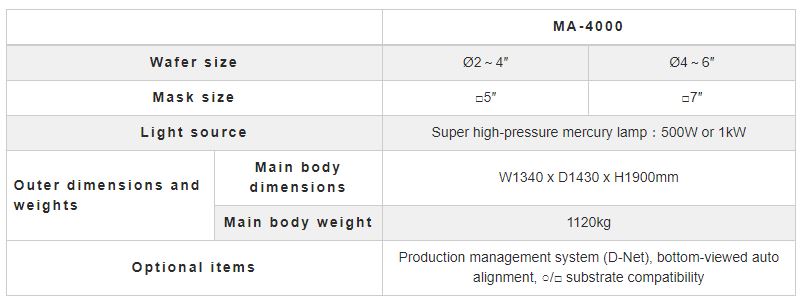

Main spec

※ Custom substrate size, mercury lamp wattage or other special spec available.

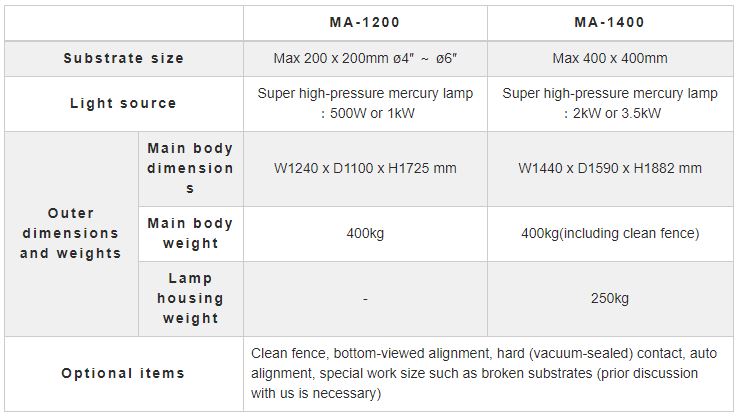

Exposure system for experimentation and research

Manually operated one-shot exposure system with a compact design.

Features

- Manually operated one-shot exposure system for experimentation and research, adaptable to glass, wafers, films and etc. Also ideal for small-lot production.

- Selectable between (soft/hard) contact exposure and proximity exposure.

- Adaptable to max. 500mm×500mm substrates. Equipped with an optical system in an optimized combination of a super-high-pressure mercury lamp (500W, 1kW, 2kW or 3.5kW), mirrors, specialty lenses, condenser lenses and etc.

Main spec

※ Custom substrate size, mercury lamp wattage or other special spec available.

Exposure system for other mass production

Exposure system that prints patterns on photoresist-coated substrates aligned with a mask.

Features

- Automatic proximity exposure system capable of exposing a substrate in its full exposure area at a time.

- Custom machine composition is available such as liquid crystal, ceramic capacitor, thermal heads or etc. to meet the customers’ requests.

- Auto alignment feature implemented. (MA-4000)