SK-E for OLED backplane

SK-EH for Touch Sensor Panel (TSP)

Coater/Developer SK-E series

This facility has drawn on its many years of expertise as the world’s number one producer of coater/developer for LCDs to create a range of systems purpose-built for the production of OLED panels.

- Coater/Developer for OLED backplane manufacturing SK-E1500G

- Coater/Developer for Touch Sensor Panel (TSP) production SK-E1500H

Features

Established following specifications to achieve Line/Space (L/S) of 1.5um and below.

1. Full use of mini-environment technologies to effectively control contamination created by suspended particles

2. ESD suppressor by conductive member, employment of Levitation Linearcoater Levicoater™, and optimized position of ionizers.

3. A two-nozzle coater is available for production lines that use multiple types of coating material.

4. SK-E1500H can process two 6th generation half-substrates simultaneously. This ability delivers sgnificant improvements in production efficiency.Specifications

Substrate Size

SK-E1500G: 1,500mm x 1,850 mm (G6)

SK-E1500H: 1,500mm x 925 mm (G6 Half)

We are The Sales Representative of SCREEN Finetech Solutions Co., Ltd. in Korea.

* Linearcoater and Levicoater are registered trademark and/or trademarks of SCREEN Holdings Co., Ltd.

for Color filter for OLED (AR films)

Coater/Developer SK-F series

The SK-F series are coater/developers specially designed for the forming process of the Color Filter (CF) films for rollable or foldable OLEDs.

This facility has leveraged its extensive experience in creating market-proven coater/developers specialized for the manufacture of OLED panels.

The SK-F series will make a significant contribution to the improvement of yield rates for OLED panels.

Features

1. The entire process from coating through development of CF films is executed in a single integrated line.

2. Designed to form CF films on the substrates with an OLED luminescent layer.

3. Two 6th generation half-substrates processed continuously.

4. ESD suppressor by conductive member, employment of Levitation Linearcoater Levicoater™, and optimized position of ionizers.

5. A two-nozzle coater is available for production lines that use multiple types of coating material.Specifications

Substrate Size

SK-F1500H1,500mmx925mm (G6 Half)Lineup of Systems Specially Designed for Production of OLED Panels

We are The Sales Representative of SCREEN Finetech Solutions Co., Ltd. in Korea.

* Linearcoater and Levicoater are registered trademark and/or trademarks of SCREEN Holdings Co., Ltd.

for PI film for flexible display

Coater Line SK-P series

The Linearcoater™ high-precision slit-type coating system has been relaunched as a Polyimide coater for flexible display. Integrated system control throughout the line maximizes productivity and efficiency of movement between units.

Features

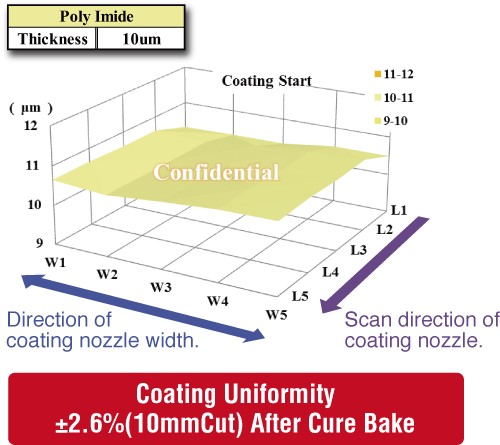

1. Excellent coating uniformity achieved

2. Piping system and high pressure resistant precision pumps are optimizd for high viscosity Polyimide material.

3. Original degas sysem enhanced productivity.

Specifications

Substrate Size

730 x 920 mm (G4) ~ 1,500×1,850 mm(G6)

* A pilot line configuration is also available.* Linearcoater is a registered trademark and/or a trademark of SCREEN Holdings Co., Ltd.

We are The Sales Representative of SCREEN Finetech Solutions Co., Ltd. in Korea.

* Linearcoater and Levicoater are registered trademark and/or trademarks of SCREEN Holdings Co., Ltd.

Business Contacts

Please any inquiries regarding product or technical information and requests for estimations.